SAFECID

Calcium Slayer and Flush 2-Step Offset Ink Roller Cleaning System

- Weight:

- 5 LBS

- Shipping:

- Calculated at Checkout

Description

Calcium Slayer and Flush 2-Step Offset Ink Roller Cleaning System

(2) 12 oz bottles in Kit

Designed for use on rubber offset printing rollers, Calcium Slayer thoroughly and safely eliminates calcium glaze. It contains no VOC's, is fully biodegradable in 10 days or less and is non-hazardous.

Calcium Slayer quickly penetrates through calcium glaze on rubber offset rollers. Utilizing patented technology, Calcium Slayer is capable of flushing out years of accumulated paper lint, previous ink deposits and other roller contaminants during usage. Calcium Slayer is not flammable or combustible, is odorless, emits no chemical fumes and carries a Triple Zero safety rating, as well as being a U.S. EPA Designed for the Environment product.

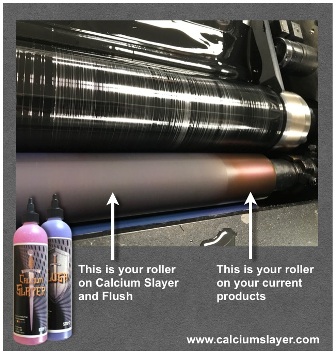

Offset printers will be astonished at how effectively Calcium Slayer cleans their rubber rollers. Calcium Slayer will extend roller life and dramatically improve ink/water balance. Calcium Slayer and Flush utilize patented technology to obliterate calcium glaze from rubber offset printing rollers.

FEATURES

- Obliterates calcium and glaze from rubber rollers

- Eliminates stripping & hickies that may be caused by glaze

- Improves ink transfer and ink/water balance

- Extends roller life and reduces ink consumption

- No VOC's. No chemical fumes. No hazmat shipping fees

- Fully biodegradable. Safe for the user and environment

Calcium Slayer and Flush Info Sheet

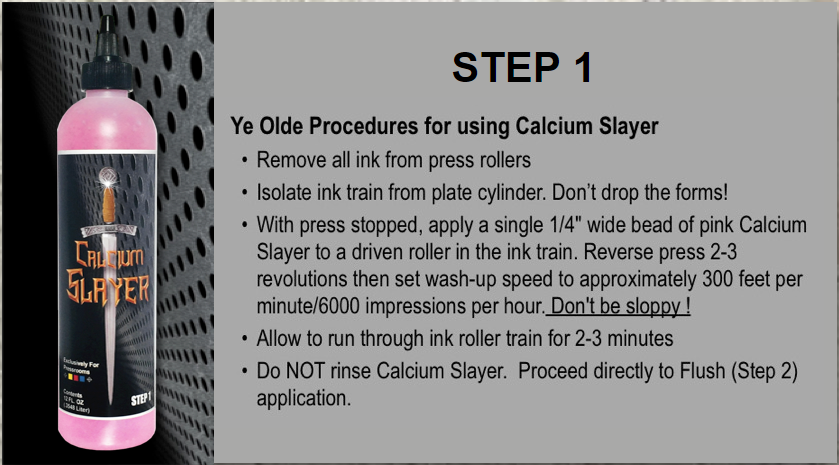

Procedures for using Calcium Slayer – STEP 1

- Remove all ink from press rollers.

- Isolate ink train from plate cylinder. Don’t drop the forms.

- With the press stopped, apply a single 1/4″ wide bead of pink Calcium Slayer to the ink roller train.

- Start the press and allow to run through the ink roller train for 2-3 minutes.

- Do NOT rinse Calcium Slayer.

- Proceed directly to Flush (Step 2) application.

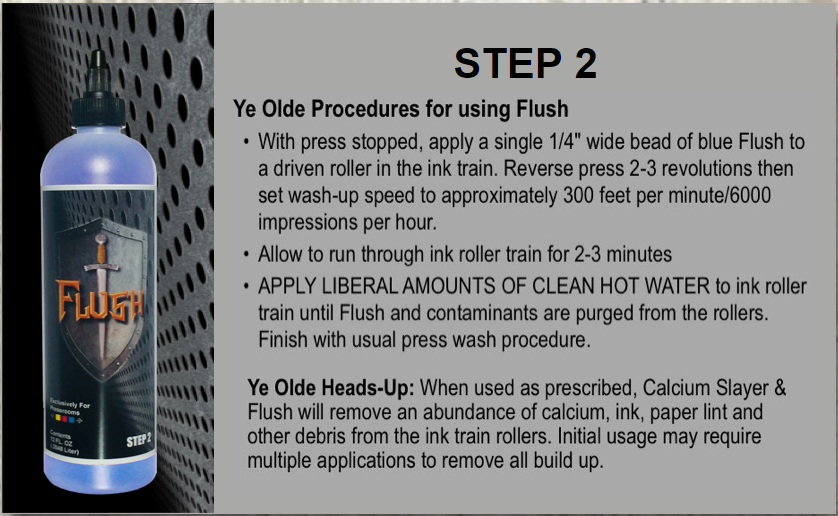

Procedures for using Flush – STEP 2

- With the press stopped, apply a single 1/4″ wide bead of blue Flush to the ink roller train.

- Start the press and allow to run through the ink roller train for 2-3 minutes.

- Apply liberal amounts of clean, hot water to the ink roller train until flush and contaminants are purged from the rollers. Finish with usual press wash procedure.

Heads-Up: When used as prescribed, Calcium Slayer & Flush will remove an abundance of calcium, ink, paper lint, and other debris from the ink train rollers. Weekly use is recommended. Initial usage may require multiple applications to remove all build-ups.

Frequently Asked Questions

What is the Calcium Slayer and Flush system?

It's a two-step cleaning system for rubber offset printing rollers designed to eliminate calcium glaze, ink deposits, paper lint, and other contaminants using patented technology.

What are the benefits of using this system?

It obliterates calcium glaze, eliminates stripping and hickies, improves ink transfer and ink/water balance, extends roller life, and reduces ink consumption. It's also VOC-free, biodegradable, and non-hazardous.

How do you use the Calcium Slayer and Flush system?

First, apply pink Calcium Slayer (Step 1) to inked rollers, run for 2-3 mins (do not rinse). Then, apply blue Flush (Step 2), run for 2-3 mins, and rinse thoroughly with hot water, followed by your usual press wash.

Is this product safe?

Yes, Calcium Slayer contains no VOCs, is biodegradable, non-hazardous, non-flammable, odorless, and carries a Triple Zero safety rating. It is a U.S. EPA Designed for the Environment product.

How often should I use Calcium Slayer and Flush?

Weekly use is recommended for maintenance. Initial usage on heavily contaminated rollers may require multiple applications.